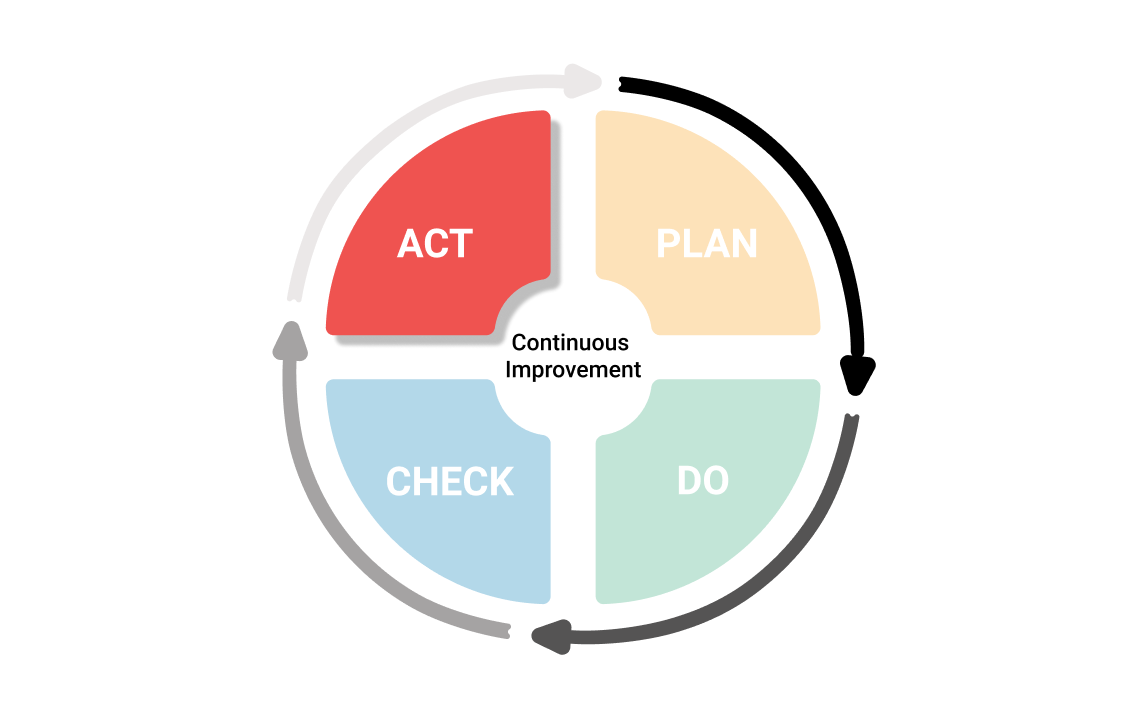

Plan Do Check Act

And everyone adopts it using the support of a coach or their leader to help them implement improvements daily. This concept is a cycle for implementing change which when followed and repeated would lead to repeated improvements in the process it was applied to.

Pdca Flat Diagram For Powerpoint Slidemodel Powerpoint How To Plan Business Powerpoint Templates

In my view it is the most basic framework for any kind of change.

Plan do check act. In fact where theres a problem it should be used to eliminate it. Plan Do Check Act or PDCA is a powerful improvement method that will let your improve your work and processes every day. The Deming Cycle mimics the rigorous scientific method without being tied.

Explained briefly the Plan-Do-Check-Act cycle is a model for carrying out change. Pengertian dan Siklus PDCA PDCA adalah singkatan dari PLAN DO CHECK dan ACT yaitu siklus peningkatan proses Process Improvement yang berkesinambungan atau secara terus menerus seperti lingkaran yang tidak ada akhirnya. Plan-Do-Check-Act or PDCA is one of the key elements in lean manufacturing or for that matter in any kind of improvement process.

It is also known as the Deming circle cycle wheel the Shewhart cycle the control circle cycle or plandostudyact. The Plan Do Check Act PDCA cycle is the operating principle of ISOs management system standards. PDCA stands for Plan-Do-Check-Act a four-stage problem-solving model that enables organizations to continually improve processes products or services.

This cycle has no end and it can be repeated over again for continuous improvement. Plan Do Check Act can be used for many different scenarios. The Plan Do Check Act cycle is a reflection of this.

Systematic Plan Do Check Act Process. The Plan Do Check Act approach achieves a balance between the systems and behavioural aspects of management. The PDCA cycle is considered a project planning tool.

It is an essential part of the lean manufacturing philosophy and a key prerequisite for continuous improvement of people and processes. Plan-Do-Check Act Model for EMS ISO 140012015. It also treats health and safety management.

- PDCA Plan for the new product development production process Analyze the collected data to measure customer satisfaction Create a prototype test it collect data from the customer Fully Implement the new design act on collected feedback Plan Do Act Check. Achieve a balance between the systems and behavioural aspects of management. Plan Do Check Act PDCA PDCA atau yang sering disebut juga dengan Deming CircleDeming CycleWheel Shewhart Cycle control circlecycle dan Plan Do Study Act PDSA adalah sebuah metode manajemen empat langkah iteratif yang digunakan pada proses bisnis untuk kontrol dan peningkatan berkelanjutan dari proses dan produk.

Plan-do-check-act is a four-step model that carries out the change in a process product or service. Just as a circle has no end the PDCA cycle should be repeated again and again for continuous improvement. The PDCA model was developed in the 1950s by William Deming as a learning or improvement process based on the scientific method of.

Therefore this cycle is called a loop. Pada tahap ini Anda. Planning for a new product development.

It is an essential part of the lean manufacturing philosophy and a key prerequisite for continuous improvement of people and processes. All other lean tools are only on top of the PDCA. PDCA plandocheckact or plandocheckadjust is an iterative design and management method used in business for the control and continuous improvement of processes and products.

It introduces a Plan Do Check Act approach to managing for health and safety that can help you. Mengenal Lebih Jauh Plan Do Check Act PDCA PDCA atau yang sering disebut juga dengan Deming CircleDeming CycleWheel Shewhart Cycle control circlecycle dan Plan Do Study Act PDSA adalah sebuah metode manajemen empat langkah iteratif yang digunakan pada proses bisnis untuk kontrol dan peningkatan berkelanjutan dari proses dan produk. Konsep siklus PDCA Plan Do Check dan Act ini pertama kali diperkenalkan oleh seorang ahli manajemen kualitas dari Amerika Serikat yang bernama Dr.

Its formal structure includes processes that regularly examine performance and ensure that the system continues to provide ongoing benefits. The approach which determines an EMS is founded on the concept of Plan-Do-Check-Act PDCA. Explained briefly the Plan-Do-Check-Act cycle is a model for carrying out change.

A brief summary of Plan Do Check Act. This model provides a constant process that allows organizations to achieve ongoing improvementPDCAs are not only applied to the EMS overall but to each of its individual elements. In my experience most lean projects in the Western world fail not because they do not have some.

The Plan-do-check-act cycle Figure 1 is a four-step model for carrying out change. But dont forget to secure the results because thats the only way to make your organization genuinely smarter. Plan-do-check-act or PDCA is a method organizations use to continually improve their internal processes increasing the quality of their products and the overall efficiency of their business.

One way to manage the risks well is to adopt the Plan-Do-Check-Act or Plan-Do-Check-Adjust PDCA cycle also known as the Deming Cycle as it was proposed by Dr. The Plan-Do-Check-Act PDCA cycle also known as the Deming wheel or the Deming cycle is an iterative method for continual improvement of processes products or services and is a key element of lean management. First proposed by Walter Shewhart and later developed by William Deming the PDCA cycle became a widespread framework for constant.

Moreover this model is considered as a project planning tool. Plan-Do-Check-Act also called PDCA is a cycle that was originated by Walter Shewhart and made popular by Edward Deming two of the fathers of modern quality control. First proposed by Walter Shewhart and later developed by William Deming the PDCA cycle became a widespread framework for constant.

Plan-Do-Check Act is short for. The steps in each successive PDCA cycle are.

Example 9 Quality Management Pdca This Example Was Created In Conceptdraw Diagram Using The Plan Do Check A How To Plan Energy Management Business Continuity

Using Plan Do Check Act Pdca To Process Teambuilding Activities How To Plan Process Control Project Management Principles

Free Plan Do Check Act Powerpoint Template Is A Free Ppt Template With A Ready Made Free Powerpoint Presentations Powerpoint Template Free Powerpoint Templates

Management Pdca Plan Do Check Act Plan Do Check Act Pdca Or Plan Do Check Adjust Als How To Plan Business Process Management Business Management Degree

Management Pdca Effective Practice Plan Do Check Act Pdca Or Plan Do Check Adjust Also Known As De Business Management Degree How To Plan Learn Business

Plan Do Check Act How To Plan Management Skills Operations Management

Plan Do Check Act Template Luxury Myndanidurstada Fyrir Pdca Cycle Management Math Lesson Plans Template Problem Statement How To Plan

Example 10 Quality Management Process Model This Example Was Created In Conceptdraw Diagram Using The Plan Do Check Act How To Plan Energy Management Acting

Ciclo Pdca Plan Do Check E Act Sistema De Gestao Ambiental Desenho De Viagem Seguranca No Trabalho

Plan Do Check Act Template Awesome Deming Wheel Pdca Cycle Powerpoint And Keynote Templat In 2021 Powerpoint Templates Infographic Template Powerpoint Keynote Template

Plan Do Check Act Learning Management Health And Safety

Pdca Plan Do Check Act Also Known As The Deming Cycle Is A Four Step Loop Used For Achieving Continuous Process Improvement How To Plan Process Engineering

Deming Cycle Definition Importance Of Plan Do Check Act Pdca Cycle 2 In 2021 Deming Cycle How To Plan Deming

Pdca Plan Do Check Act Continually Improving In A Methodical Way Problem Solving Model How To Plan Math Lesson Plans Template

Posting Komentar untuk "Plan Do Check Act"